What is Welding?

Welding is a process that fuses two or more materials, typically metals, by using heat, pressure, or both. This creates a permanent bond known as a weldment, and the original pieces being joined are called the parent materials. The material added to help form the weld is known as a filler or consumable. Welding is used in manufacturing, repair, and fabrication across a wide range of industries. Some people would say welding is an art form since some materials require specific processes or techniques.

Thinking about starting a career in welding? It helps to know some key industry terms, applications, and more. We’ll break down the most important types of welding, joint configurations, and processes, plus how you can start a career in welding.

Types of Welds

Welding Joints Based on Configuration

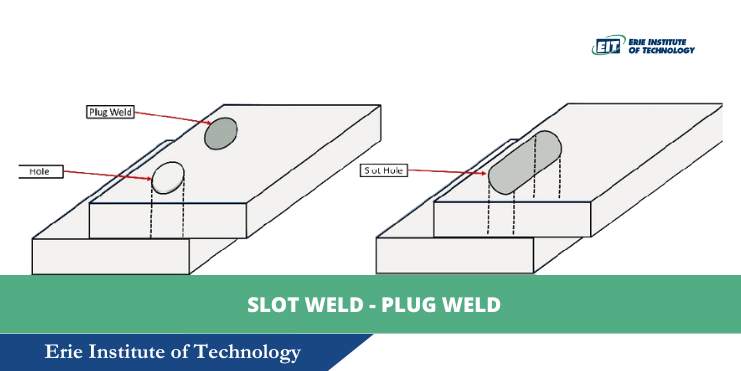

Slot Weld

A slot weld is a joint between two overlapping parts. It’s created by depositing a filet weld around the edge of a hole in one part that’s joined to the second part through the exposed surface of the hole.

Plug Weld

To create a plug weld, you’ll use a filler metal to join one part to the surface of another overlapping part through the hole.

Welds Based on Penetration

Full Penetration Weld

Also known as complete joint penetration (CJP), full penetration welds occur when the weld metal fully penetrates the joint with complete root fusion.

Partial Penetration Weld

A partial penetration weld occurs when the weld metal is intentionally not fully penetrating. You may also hear this type of weld referred to as partial joint penetration (PJP).

Slot and Plug Weld – Types of Joints

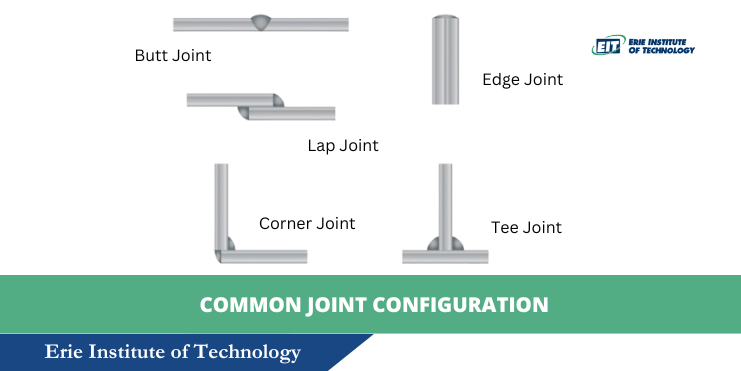

Common Joint Configurations

- Butt Joint: Ever heard the term “butting up against?” A butt joint does just that. Butt joints connect the edges of two parts, forming a 135° to 180° angle.

- T Joint: This configuration connects the end or edge of one part and the face of another, with the two parts forming an angle greater than 5° but no greater than 90°.

- Corner Joint: Corner joints connect the ends of two parts at an angle between 30° and 135°.

- Edge Joint: An edge joint connects the edges of two parts to form one that is between 0 to 30°.

- Cruciform Joint: This is a connection where two flat bars or plates are welded to another flat plate at right angles and aligned on the same axis.

- Lap Joint: Lap joints form a connection between overlapping parts that create an angle of 0-5°, which is included in the welds.

Common Joint Configurations

Main Welding Processes

1. Gas Metal Arc Welding (GMAW/MIG)

Gas metal arc welding, sometimes called MIG welding, uses a thin wire as an electrode and is typically used in construction and automotive applications. You’ll typically use this process on metals like copper, stainless steel, nickel, and more.

During MIG welding, the wire heats up as it’s fed through the welding instrument. To keep air containment out of the weld, you must use a shielding gas like carbon dioxide, oxygen, argon, or helium.

Gas Metal Arc Welding (GMAW/MIG)

2. Gas Tungsten Arc Welding (GTAW/TIG)

Also known as TIG welding, this process is typically used for welding thin and non-ferrous metals like aluminum, copper, lead, or nickel. TIG welding is different from other processes because it uses a non-consumable tungsten electrode to form a weld.

Common applications for this welding process include bicycle or aircraft manufacturing.

3. Shielded Metal Arc Welding (SMAW/Stick)

Often called stick welding, shielded metal arc welding is a common process used among home-shop welders. This process involves manual techniques using a flux-coated electrode consumable.

Stick welding is not known for its high quality or durability, however, it’s one of the most low-cost processes.

4. Flux Cored Arc Welding (FCAW)

Flux-cored arc welding involves continuously feeding a wire as your weld, much like MIG welding. However, flux-cored arc welding is broken into two distinct processes.

One uses a shielding gas. The other uses self-shielding agents produced when fluxing agents decompose within the wire. This process makes it possible to weld in outdoor conditions.

FCAW is commonly applied in construction projects because the semi-automatic arc provides high welding speeds and portability.

Other Welding Methods Include:

- Submerged Arc Welding (SAW)

- Gas Welding/Oxyacetylene Welding

- Thermit Welding

- Forge Welding

- Electron Beam Welding

- Atomic Hydrogen Welding

- Plasma Arc Welding

- Resistance Welding

Why Welders Are in High Demand

According to the American Welding Society (AWS), there will be a massive welder shortage by 2024. Estimates show the industry will face a staggering 400,000 worker shortage. This is likely due to a large portion of the industry retiring.

This creates more opportunities for people looking to start a new career or switch careers to welding. All you need to do is get the right training and education to gain the experience you need to become a skilled welder.

How to Become a Qualified Welder

Starting a new career or switching careers can seem like an uphill battle. But when you attend a skilled trade training program dedicated to your success, you’ll realize how attainable your goals really are.

At EIT, our welding program provides you with the practical experience and hands-on training employers seek. Check out what our one-year welding program can offer you.

Ross Aresco

CFO

Ross Aresco is the CFO of Erie Institute of Technology. Erie Institute of Technology (EIT) is an Erie Pennsylvania technical/trade school providing training programs for medical, computer, electronics, manufacturing, and technology careers. EIT offers programs in many different areas to suit your interests and talents.